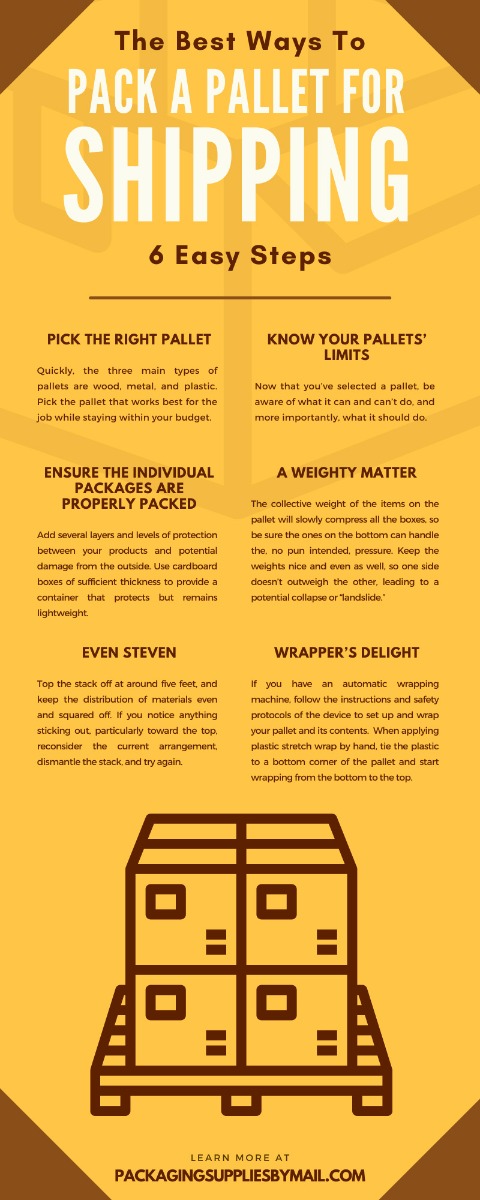

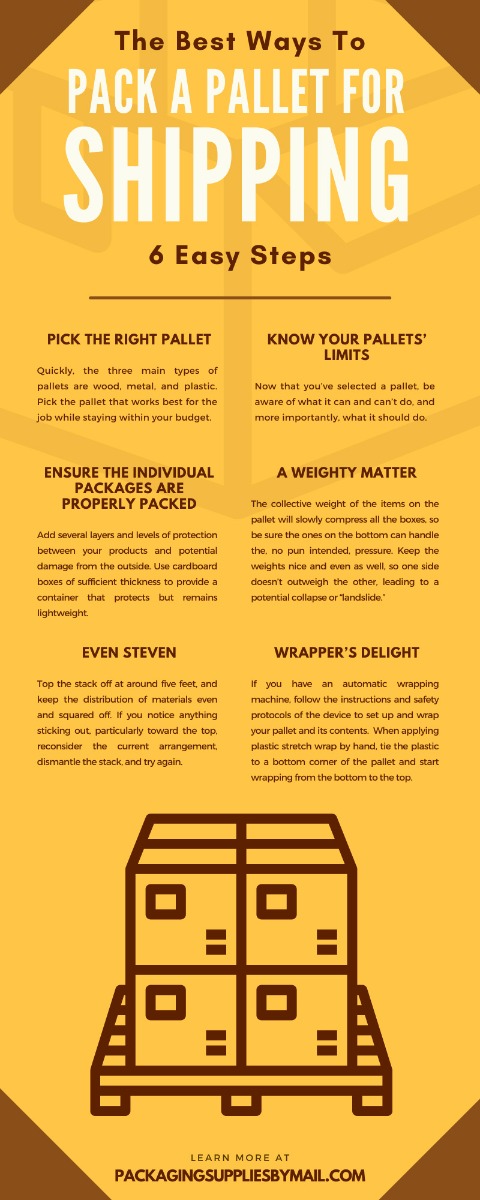

Packing pallets might look simple, but it’s one of the most crucial parts of the shipping process. A poorly packed pallet can cause product damage, wasted materials, and even safety risks for workers. The good news? With the right materials and techniques, you can ensure every pallet is stable, secure, and ready to ship.

Here are the six best ways to pack a pallet for shipping safely and efficiently.

1. Pick the Right Pallet

When most people think of pallets, the classic double-decker wooden design comes to mind. But pallets are made from several materials—each with unique strengths.

-

Wood Pallets: Tough, repairable, and cost-effective. Ideal for heavy loads, though their weight can increase shipping costs. Over time, they may warp or splinter.

-

Plastic Pallets: Lighter and resistant to moisture or corrosion. However, they’re pricier and harder to repair than wood.

-

Metal Pallets: Extremely durable and strong, but heavy and expensive. Best suited for long-term or high-stress use.

Choose the pallet material that best fits your shipment type and budget.

2. Know Your Pallet’s Limits

Every pallet has a maximum weight capacity and height limit—and exceeding them risks collapse or injury.

-

Weight: Most pallets can safely support between 2,500 and 2,800 pounds.

-

Height: Avoid stacking more than six feet high to prevent toppling.

Always place heavier, sturdier items on the bottom and lighter or fragile items on top. A balanced load is a safe load.

3. Ensure Proper Packing and Protection

Before wrapping, protect your products from impact, moisture, and shifting.

-

Add cardboard or plastic dividers between layers.

-

Use bubble wrap or honeycomb wrapping paper for fragile items.

-

Secure loose boxes with packing tape.

-

Wrap the entire load with stretch wrap to prevent movement during transit.

The goal is to create multiple layers of defense between your products and potential damage.

3. Ensure Proper Packing and Protection

Before wrapping, protect your products from impact, moisture, and shifting.

-

Add cardboard or plastic dividers between layers.

-

Use bubble wrap for fragile items.

-

Secure loose boxes with packing tape.

-

Wrap the entire load with stretch wrap to prevent movement during transit.

The goal is to create multiple layers of defense between your products and potential damage.

4. Stack with Stability: Weight and Shape Matter

Stacking technique can make or break your pallet’s stability.

-

Build upward, not outward — think cube, not pyramid.

-

Rotate each layer like a brick pattern rather than stacking columns. This locks boxes in place and reduces shifting.

-

Keep the weight even across all sides to prevent tipping.

-

Make sure the boxes on the bottom can handle the load above.

A cube-shaped pallet distributes weight evenly and moves safely through warehouses.

5. Keep It Even and Square

Before wrapping, take a moment to check your work:

-

Keep edges straight and squared.

-

Avoid overhang—boxes should not extend past the pallet.

-

Insert flat cardboard sheets between layers to spread pressure.

-

Add corner boards for extra support and protection.

An even stack helps the wrap and straps do their job more effectively.

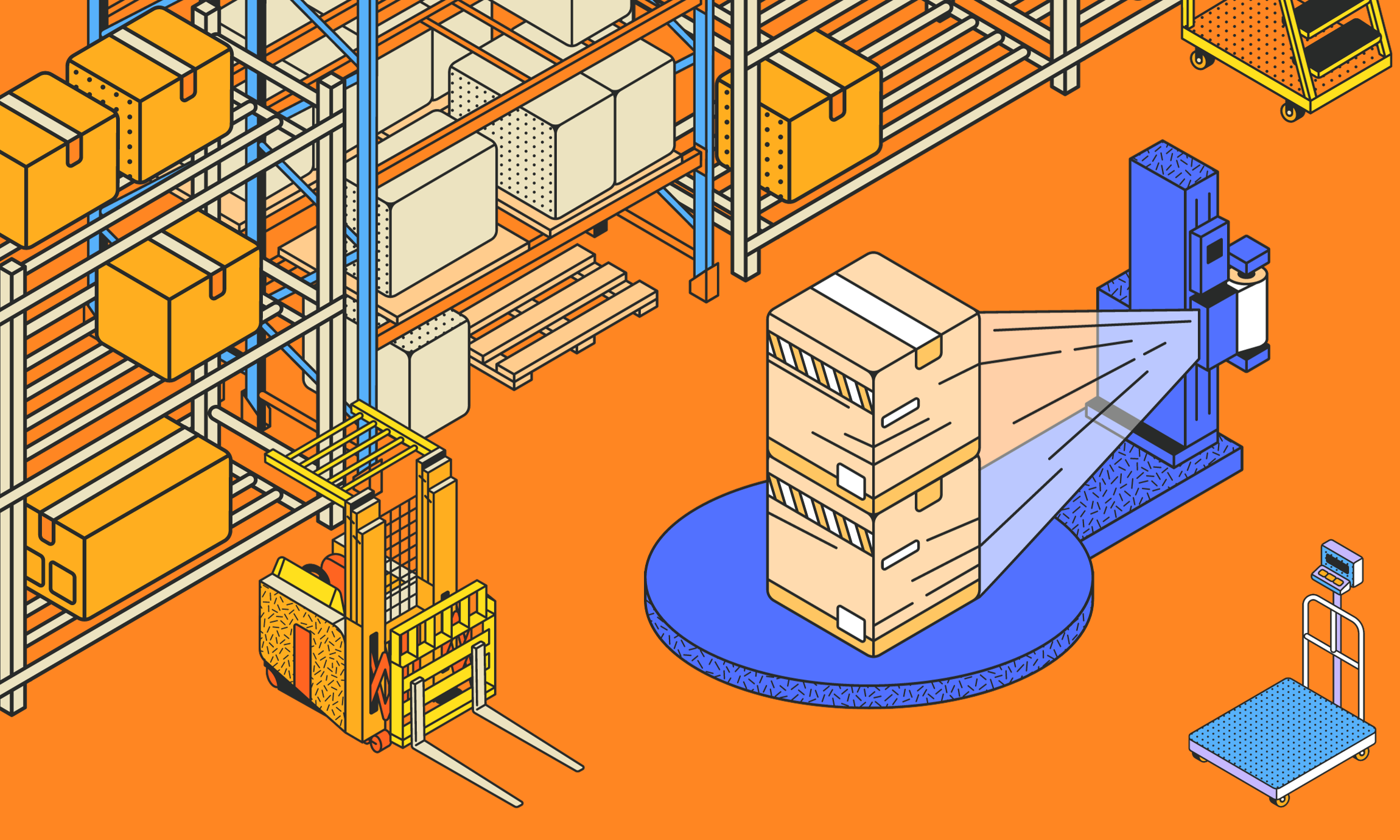

6. Wrap and Secure the Pallet

Now it’s time to seal everything in place.

-

Use packing bands (polypropylene, polyester, rayon, or steel) to strap down the load.

-

Once strapped, use stretch wrap or machine wrap for the final seal.

-

If wrapping by hand, start from the bottom and work upward.

-

Overlap each layer twice, finishing with four layers total for full coverage.

Pro Tip: Keep tension consistent while wrapping — too tight and you’ll crush boxes, too loose and they’ll shift in transit.

Quick Recap: 6 Steps to a Perfect Pallet

-

Pick the right pallet for your shipment.

-

Know your pallet’s limits (weight and height).

-

Add layers of protection and proper packing materials.

-

Stack evenly and think cube, not pyramid.

-

Keep corners square and weight balanced.

-

Wrap and secure with stretch wrap and bands.

Packing a pallet properly takes a little time, but the payoff is huge — fewer damages, safer handling, and happier customers. With consistent practice, your team will build perfectly balanced, shipment-ready pallets every time.

Ready to Get Started?

Explore our full range of stretch wrap and packing tape to make pallet packing faster and safer.

Visit our Stretch Wrap Collection to find the right film for your next shipment.

Sign In